Normally, the center axis of the sprue bush of the mold is parallel to the direction of the opening mold, and the center axis of the sprue bush is right in the center of the mold. If due to product appearance requirements or structural impact, the position of the glue must be eccentric, if the eccentricity is very large, should consider the hot runner and another way of entering the glue.

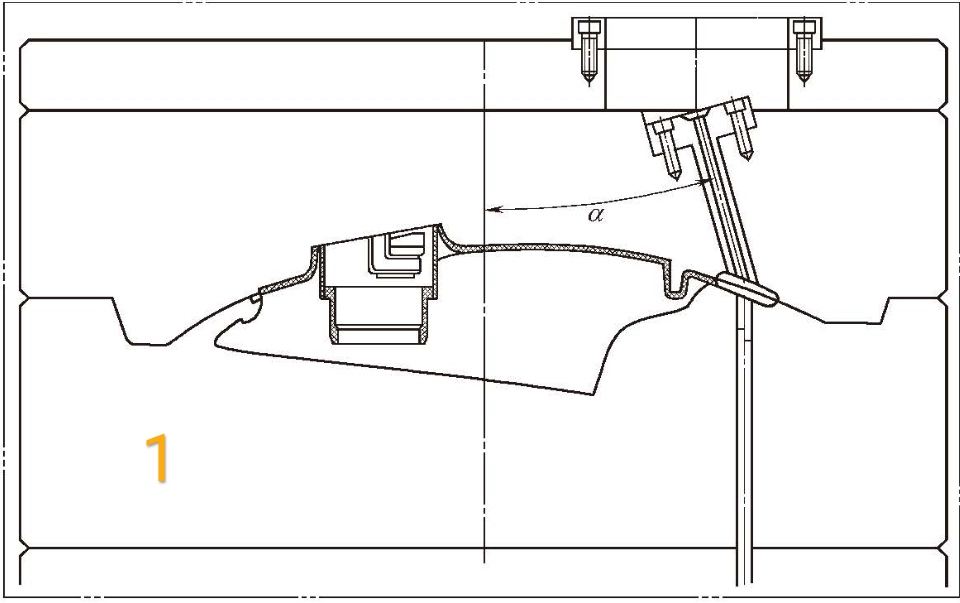

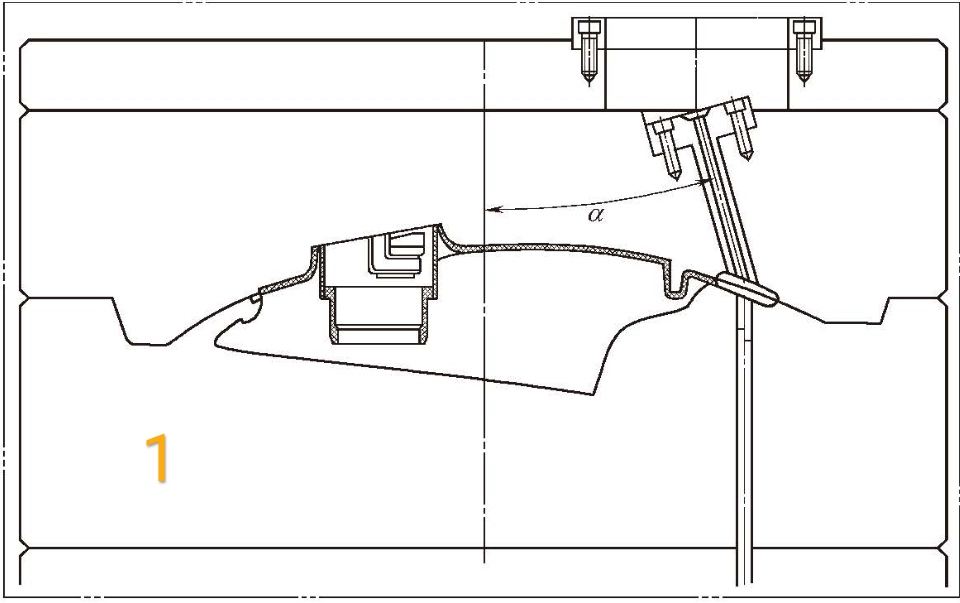

When eccentricity is appropriate, in order to reduce the impact of the imbalance of the clamping force on product quality and the damage to the injection molding machine, the sprue bush can be appropriately tilted to reduce the eccentricity of the sprue bush, the slant sprue bush mould is shown in Figure 1.

Design specifications:

1. The slant sprue bush is suitable for plastics with better toughness. Fragile plastic such as PS is not suitable for slant sprue bush, plastic is easy to break in the sprue bush.

2. In order to ensure safety, the inclination of the sprue bush (α angle in Figure 1) is generally not more than 12 ° and the maximum is not more than 15 ° except for soft plastic.

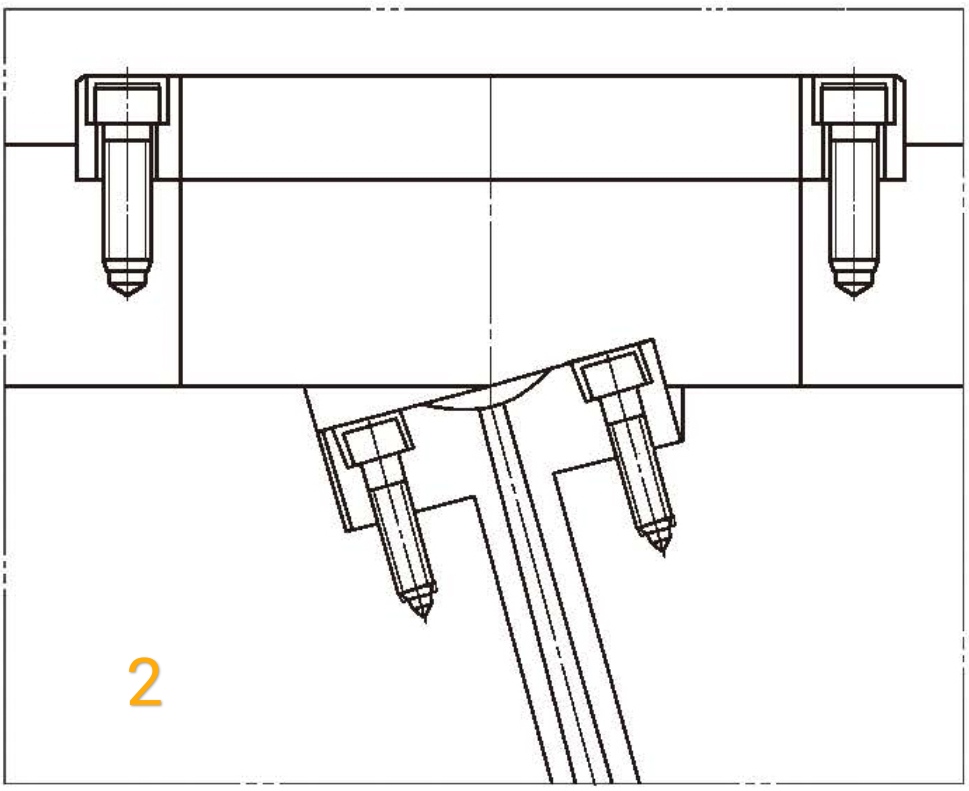

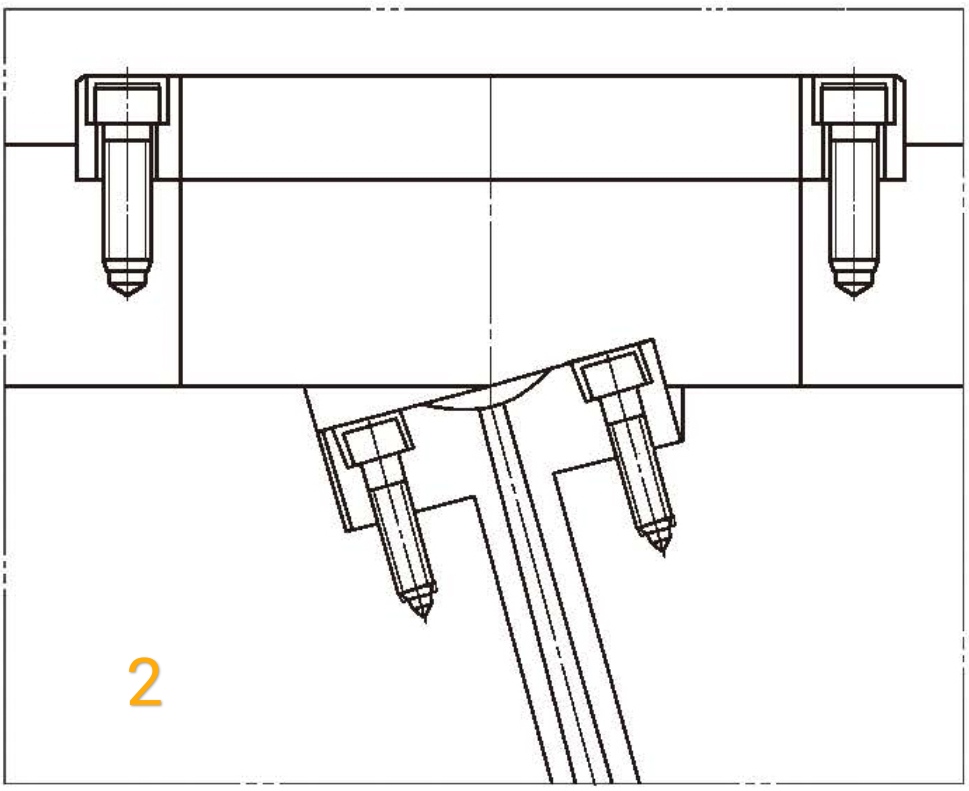

3. When designing the mould, the center of the sprue bush must be on the same axis as the center of the locating ring, as shown in Figure 2.

4. The center of the knock-out holes must be aligned with the center of the locating ring. If the mould is eccentric, the knock-out holes must be synchronized moved.

5. When we do the slant sprue bush, if the mold is still too eccentric and the mold structure allows, other ways of glue feeding can be considered, such as hot runner, edge gate, etc.

6. The eccentricity of the left and right sides of the mold is shown on the left side of Figure 3, which is easy to affect the size of the injection molding machine used in production. The eccentricity of the top and bottom side is shown on the right side of the figure, which has little impact on the size of the injection molding machine. Therefore, attention should be paid to the direction of the mold when arranging the positions.

4. The center of the knock-out holes must be aligned with the center of the locating ring. If the mould is eccentric, the knock-out holes must be synchronized moved.

4. The center of the knock-out holes must be aligned with the center of the locating ring. If the mould is eccentric, the knock-out holes must be synchronized moved.