To solve the difficulty of the product remaining after the mold ejection, we need to do the analysis first, the design in this article is only for one situation.

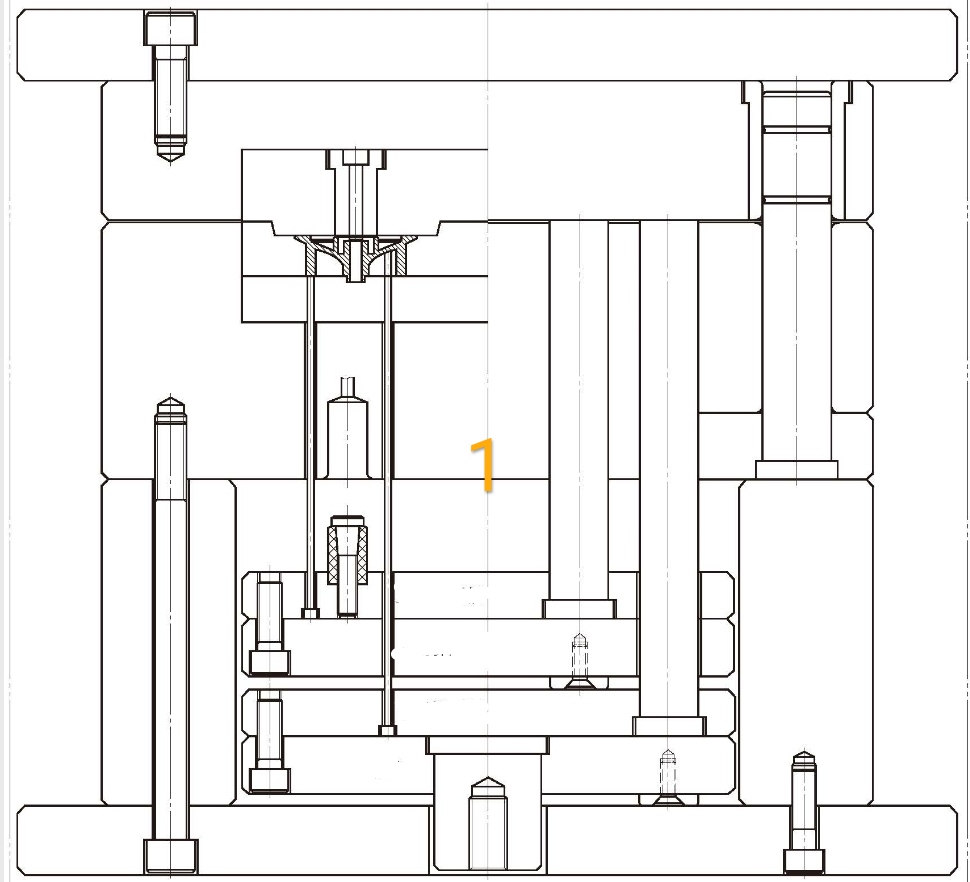

One time ejection and double return system is shown in figure 1 and figure 2, it mainly used for automation mold production, after the mold is ejected but the product still need to hang on the ejector pin or it will affect the automation production once it falls down automatically, we also need to consider of this system when the product hugs the flat ejector pin or you need to take out the product with big force or by shaking the product.

Principles:

1. When opening the cavity, knock-out directly against the ejector base plate, pushing the two groups of ejector plates to complete the ejection at the same time.

2. After completing the ejection, knock-out return first, under the pull force of knock-out, ejector base plate returned also, as the ejector retainer plate has been locked by parting lock, it still keeps ejection status.

3. After taking out the product, if the group of up ejector plate doesn't have been affected by other structure, can push it back by the cavity when shutoff, if not, you should do the return system firstly.

Design specifications:

1. The system must do two groups of ejector plates, putting the ejector pin blocking the product or the flat ejector pin hugged by the product on the second group of ejector plate, as shown in figure 1.

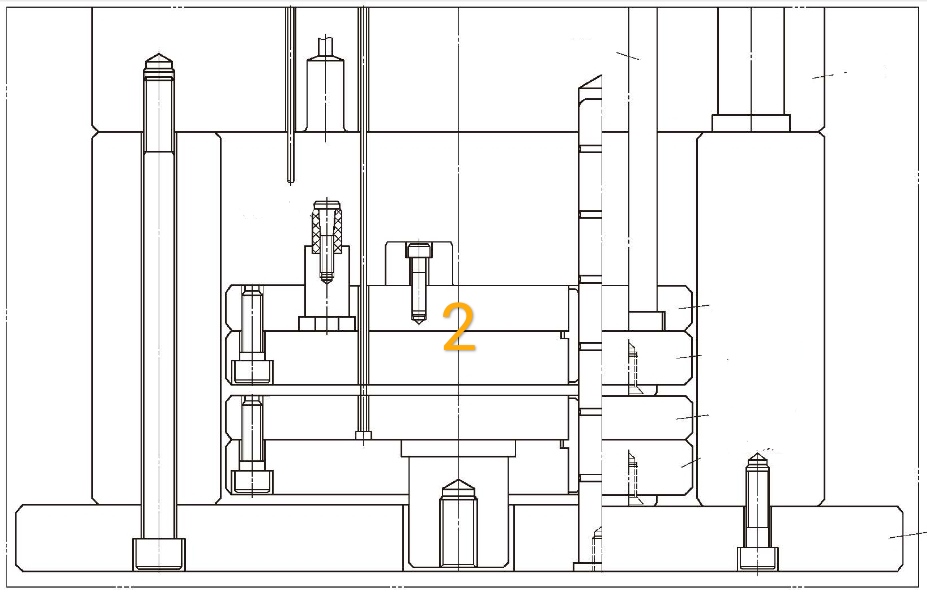

2. The up ejector plate needs to have a parting lock designing the parting lock hole under the bottom of plate B. If the ejector plate limit pin is a little bit higher, then you need to put a round pin under the parting lock, or the length of the parting lock is not enough to insert in its hole, as shown in figure 2, the location of the parting lock should be beside as much as possible to adjust or replace the parting lock freely.

3. Each group of the ejector plate should have a separate return pin. If the space of the mold is limited, not allowed doing two groups of return pin, you can think of doing the return pin on the up group of the ejector plate but it must have an ejector guide pin, as shown in figure 2.