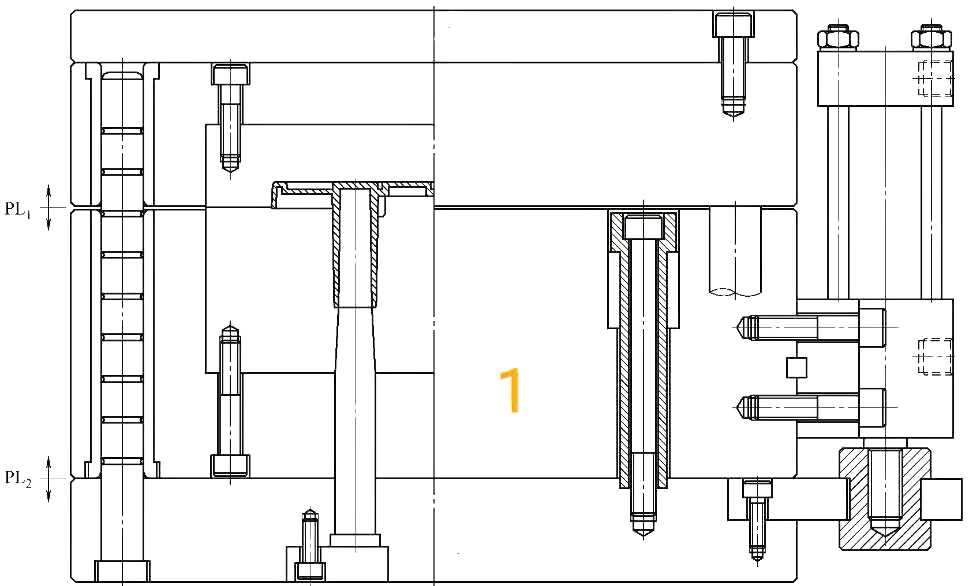

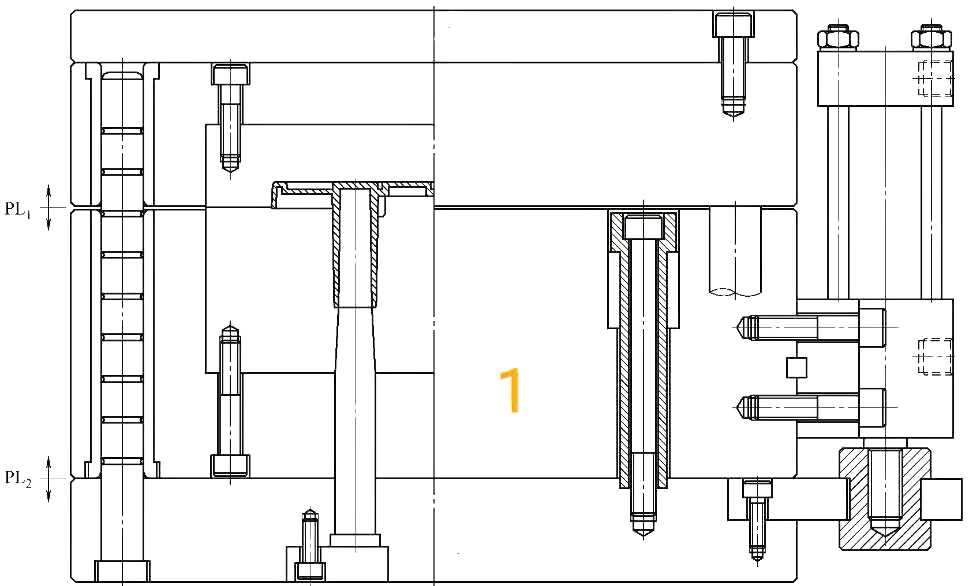

The hydraulic priority core-pulling refers to the hydraulic actuation to complete core-pulling, in this way, it is relatively simple from the structure, the action can be carried out alone, mainly used in other core-pulling structure in the mold action when there is conflict, as shown in figure 1.

Action principle:

1. Open the PL1 part first.

2. When the hydraulic push the stripper plate to the stop stroke of the limit pin, the push block is separated from plate B totally, in other words, completed the PL2 mold opening.

3. Mold ejection

Design specifications:

1. Need to do stop location between the stripper plate and plate B, the stop stroke is equal to the distance of the priority core-pulling.

2. The hydraulic should be placed on both sides to ensure force balance.

3. If the ejector plate needs to move along with the stripper plate synchronously, you can do a block on the return pin.

4. If the ejector plate has to be returned back and also needs to be ejected with stripper plate synchronously, can only do a mechanical early return system, forbid to pull it back by force, otherwise, there are opposing forces between the two components.

5. The force point of the spring of the ejector plate should be acted on the stripper plate by plate B, otherwise, the spring and the hydraulic will have an opposing force, and the retainer block can be increased if the spring length is not enough.