Core hydraulic ejection is often used when the knock-out eccentricity causes the ejection to be unbalanced, or when the mold structure is difficult to complete by knock-out ejection alone.

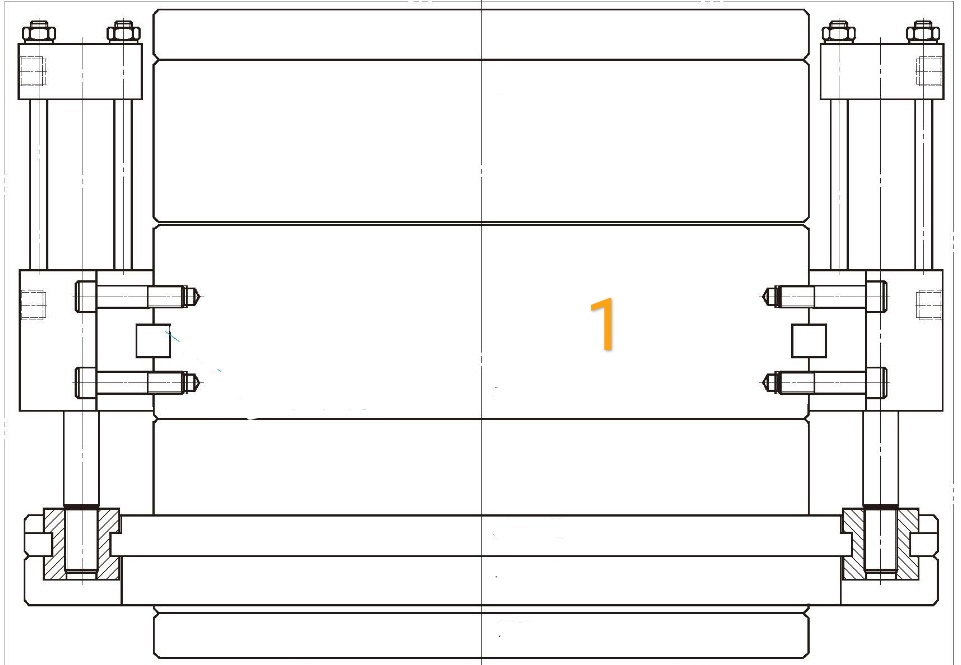

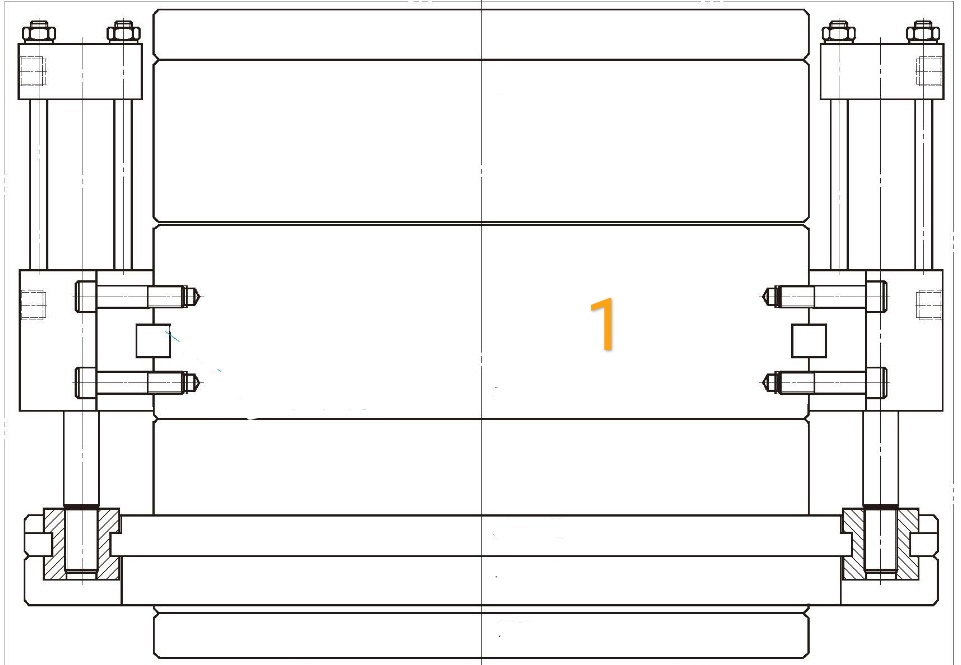

The core hydraulic ejection is similar to the cavity hydraulic ejection system, it's shown in figure 1 below.

Design specifications:

1. When we do a hydraulic ejection system, we often stick out the ejector plate and hangs the hydraulic block directly on the ejector plate.

2. For balance, the position of the hydraulic on the left and right should be obliquely symmetrically distributed centered on the ejector plate.

3. It could be better to use a locater block as the location part between the hydraulic and the mold, to ensure that the direction of the hydraulic is parallel to the direction of the ejector plate

4. The left and right hydraulic ejections must be synchronized, and the two hydraulics must be in one group.

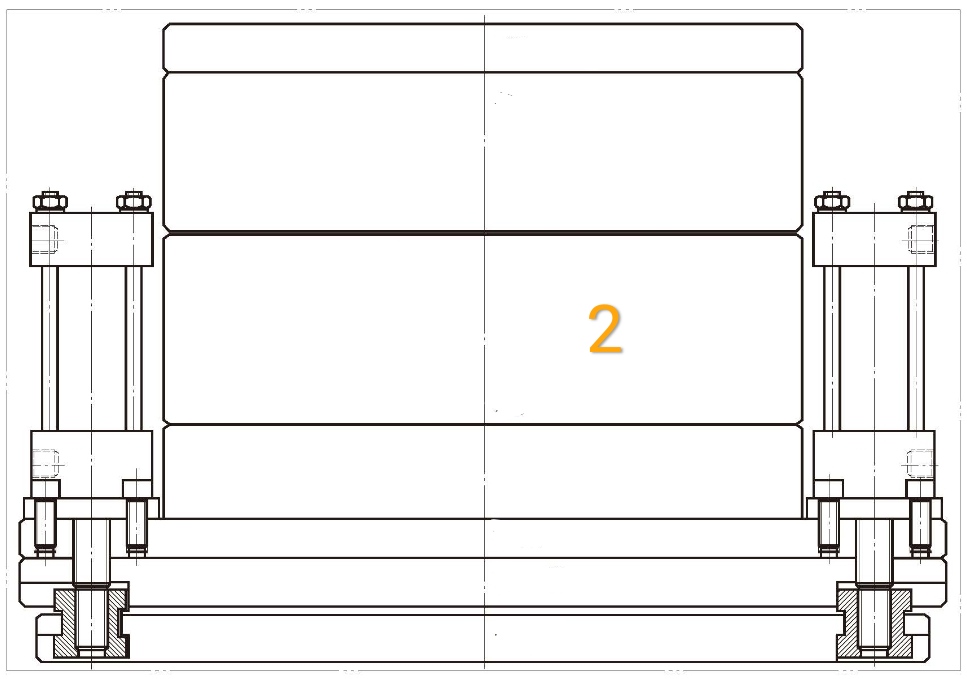

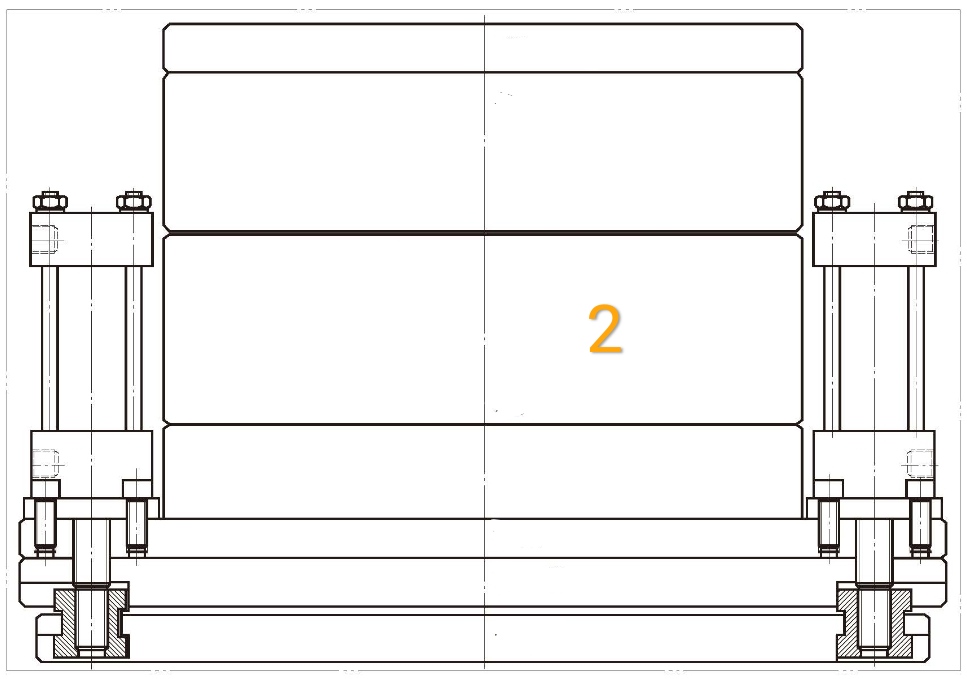

5. If the ejection stroke is too long, affected by the mold thickness, the length of the hydraulic is longer than the top clamp plate, as shown in Figure 2, the hydraulic can be installed directly on the ejector plate, which can effectively increase the utilization of mold space.

6. The verticality of the hydraulic in figure 2 is better than the verticality in figure 1, but the ejector plate takes up a lot of space. For the same mold, the ejector plate will be longer than in figure 1. If from the mold stability and processing accuracy, the use of figure 2 can be better to ensure the quality and stability of the mold.